Glasfaser-Flugzeug-Service

GmbH

Hansjörg Streifeneder

Hofener Weg 61

D-72582 Grabenstetten

FON +49 (0)7382 / 1032

FAX +49 (0)7382 / 1629

Approval according to

EASA PART 21 DE.21G.0080

EASA PART 145 DE.CAO.0060 |

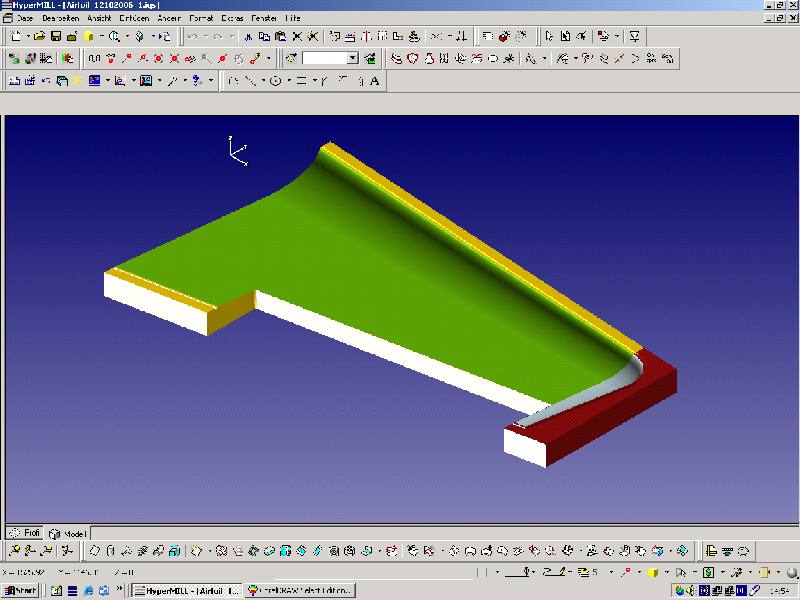

CAD / CAM For the preparation of drawings, surfaces and milling programs we

use the most modern CAD/CAM software as well as hyperMill for generating the milling

program. Combined with the simulation software, this program offers highest processing

safety and best quality. Profile processing is carried out with special programs which

were developed especially for our purposes by engineers and scientists from aerospace

technology.

We are able to process the following CAD formats:·

- DXF ·

- DWG ·

- Inventor-Dateien (iam, idw, ide, ipt, ipn) ·

- think design (e3, e2, ghd)·

- IGES·

- VDA·

- STEP·

- SAT·

- Pro/Engineer (prt, asm) ·

- CatiaV4 (after prior consultation)·

- CatiaV5 (after prior consultation)

Others on request. |

|

CNC Technique

Our new manufacturing techniques for composite aircraft

molds and other products benefit significantly in time and cost savings as well as in

quality.

With this technique we have already produced many molds

such as for wind channel models, gliders, motor aircrafts, small scale models, car bodies

and parts for the large airplane industry. Thus, glider manufacturers enjoy significantly

more flexibility in developing new prototypes. Mainly, we use polyurethane and epoxy resin

model plates for the production of positive and negative molds. Complicated parts for

controls and fittings made of aluminium or steel too can be manufactured with high

precision. So almost all complex outlines can be manufactured with our mould controlling

technique.

For parts which exceed the maximum size of our machine, we

have developed special methods which enable us to manufacture molds of the length of 31

meters or larger (see ETA molds).

List of references

- Airbus Defence and Space GmbH

- Airbus Toulouse

- MAN Technologie Ausgburg

- Fischer und Entwicklungen / Landshut

- Aquila techn. Entwicklungen GmbH

- DG-Flugzeugbau GmbH

- Schempp-Hirth Segelflugzeugbau

- Alexander Schleicher Segelflugzeugbau

- Rolladen-Schneider

- DLR Braunschweig

- DLR Berlin

- DLR Stuttgart

- Steinbeis Transferzentrum für Aerodynamik und Leichtbau

Stuttgart

- Windkraftanlagenhersteller

|

|

|